Our History

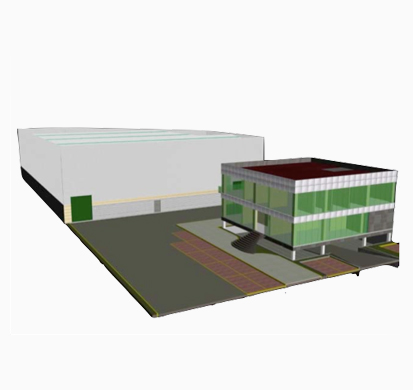

Infrastructure

Each working group at Integración de Sistemas de Actuación, S.A. de C.V. has necessary infrastructure and PPE to perform all activities in our contracts.

Mission

Support the domestic market with valve automation, based on integral pipeline solutions; developing national engineering, design and manufacturing solutions; and use state-of-the-art technology to improve productive processes, tailoring more efficient solutions which contribute to a safer and more reliable environment for the Mexican industry.

Vision

Work on innovation of designs, solutions and engineering to meet requirements of national clients, and achieve international expansion with highly reliable and competitive products for all markets, always relying on Mexican developed engineering contributing to the wealth of our great nation.

Integral policy

Integración de Sistemas de Actuación, S.A. de C.V. (INTESISTA) is committed to providing clients with high quality automation products and services on a timely manner, as well as complying with technical, legal, and management standards. Likewise, we comply with other requirements, which include environment protection commitments, pollution prevention, and protection of our personnel from work related injuries and diseases through continuous improvement of quality, environmental, and health and safety management practices.